Work Within the Mills

By: Kaila R., Melanie J., Michael P.,

and Danny N.

What was it like inside the mills?

What type of machinery was used?

What materials did the mills produce?

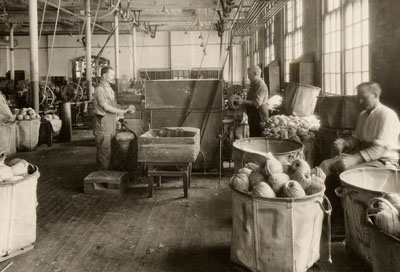

Shaping and Binding Balls of Marline

“The tightly wound ball must be shaped in the middle

before being wrapped with a piece of the marline,

to insure the binding being secure.”

Ludlow Manufacturing Associates

Within our group we examined old photographs and text describing the pictures of the old Ludlow Mills. These photos did not have specific dates, but we guessed that they were taken in the early 1900’s. On the backs of the photos were inscriptions written in pencil describing the pictures. These were probably written by someone who experienced all of the different parts of the mills at one time. When we examined them we used magnifying glasses to help read and translate the words we couldn’t understand. We learned what was manufactured at the mills and saw some of the first hand labor that was done on the machines. Some products the Ludlow Manufacturing Associates produced were twine and marline; marline is a tightly woven string that is light and made with two strands. The conditions inside of the mills were very dirty and dusty, which probably made it hard to work all day long.

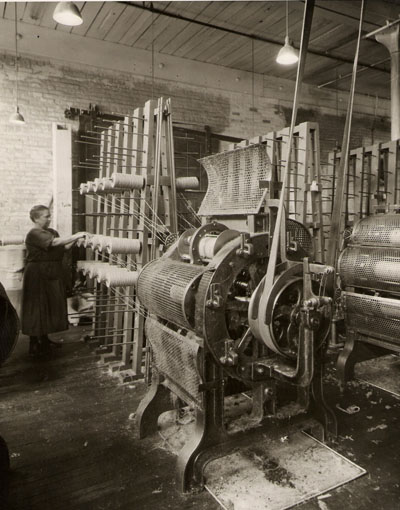

A Tubing Machine

“Here varying ply coarse twines are prepared

in such a manner that

the twisted strand will remain

as one strand when delivered from the machine.”

A Yarn Spinning Room

“’The busiest room in the mill.’” Here thousand

upon thousands of whirring spindles

spun yarn from the rove sent up from up from

the preparing department.

The humidity of the atmosphere is maintained at a

relatively

high figure to facilitate the spinning process.”

The challenging part about this project was translating and reading the old text on the pictures, and trying to understand what the people were doing in the pictures. These sources gave us a sense of what the old mills were like in the early 1900’s. The conditions inside the mills were not the greatest. The mill rooms were probably very loud and there was a great amount of humidity. Breathing for people with respiratory problems must have been a nightmare. The Ludlow mills drastically changed Ludlow, not only by population, but also new opportunities for immigrants who came to the United States. The mills brought new construction and industrialized the town. Most of the workers in the mills were either Polish or Portuguese immigrants by the early 1900’s. Because of those workers then, we now have a very large population of those ethnic groups in Ludlow.